Perforation Ball Sealers rcn ball sealers

Perforation Ball Sealers rcn ball sealers. Ball sealers were first introduced as a diverting agent in the early 1950’s using solid balls coated with rubber-coated neoprene for sealing. It was not until 1998 that the oil and gas industry started using soluble ball sealers or dissolvable perf balls. The original materials only had limited applications and over time complex copolymer plastics were replaced for most applications. This year Perf Sealers is developing floaters and near buoyant soluble ball sealers for higher efficiency in vertical and horizontal wells.

Perforation Ball Sealers rcn ball sealers

Perforation Ball Sealers rcn ball sealers

Perforation Ball Sealers rcn ball sealers

Perforation Ball Sealers rcn ball sealers

THE HISTORY OF PERFORATION BALL SEALERS IN THE OIL AND GAS INDUSTRY

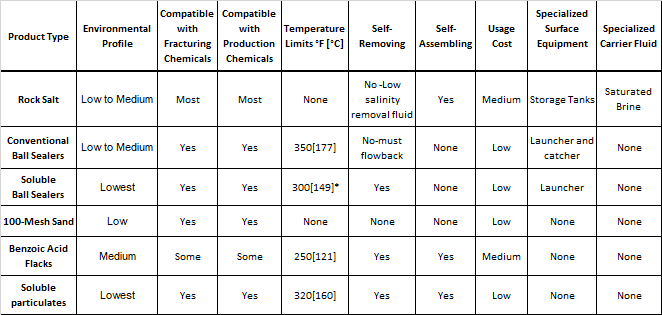

Perforation ball sealers are defined in Schlumberger’s oilfield glossary as “small spheres designed to seal perforations that are accepting the most fluid, thereby diverting reservoir treatments to other portions of the target zone.”¹ Ball sealers and solid-particle agents are one of the most economical types of diverting materials used instead of a costly packer system often requiring a rig. An overview of oil and gas completion diverting materials can be compared in Table 1.

*PS-HT rated to 300°F [149°C]

Table 1 – Overview of Common Diverter Materials

Charles Simmons was the first known inventor to use ball sealers in a well in 1953. Charles was working at Western Company of North America when he went to a dime store in Borger, Texas and bought 40 soft jack balls. He cut open the jack balls and inserted regular marbles inside them. He tested the casing perforations at the Borger district yard to make sure the holes would be plugged by the ball sealers.³ As hydraulic fracturing techniques developed, commercial wells were successfully completed in the mid 1950’s. In early 1956, the oil and gas industry documented the use of perforation ball sealers as being significantly lower in cost than conventional packers.⁴As conventional ball sealers were continually used in the industry, guidelines were added to help optimize perforation sealing efficiency in 1963.⁵ There were three basic types of ball sealers used in the industry, non-buoyant balls (Sinkers), buoyant balls (Floaters), and neutral buoyant balls. For vertical wells the non-buoyant balls usually had 50 to 100% excess of the number of perforations used based on the flow rate. ⁶ In 1992, additional testing was done to determine that in vertical wells non-buoyant balls provided the best efficiency, while neutral buoyant balls were the best in horizontal wells.⁷ In the late 1970’s ball injectors (Ball Guns) were used to pressurize the stream directly into the well during completion. Ball injectors can reach pressures up to 15,000 psi [103 MPa] using a manual hand crank or a remote controlled motor. The conventional ball sealers are available in different densities and materials such as rubber, nylon, or phenolic with the most common sealing ball surface being rubber-coated nylon (RCN). The most popular size ball sealers are 7/8 inch [22.2 mm] but other sizes are used from 5/8 inch [15.9 mm] to 1 ¼ inch [31.8 mm]. Conventional ball sealers have limitations in many perforated well completions. Non-buoyant balls can be difficult to drill out plugs and retrieve tools below perforations. Buoyant and neutral buoyant balls require a ball catcher to make sure any chokes, production equipment, or restrictions are recovered. All conventional ball sealers also can be stuck on the perforations in low pressure reservoirs and may require a wiper run to knock off the balls.In 1998 water-soluble ball sealers were first invented using collagen to address the conventional ball sealers’ issues stated above. The collagen balls only had a reservoir temperature range of 100°F [38°C] to 200°F [93°C].⁸ Eventually complex copolymer plastic water-soluble ball sealers were replaced to provide a range of 75°F [24°C] to 300°F [149°C] reservoir temperature. The mechanical integrity can be up to 4000 psi [27.6 MPa] after 1 hour of exposure at 230°F [110°C] (PS-HT). Perforation ball sealers have been in the industry for over 60 years. Ball sealers are still a staple used today in acidizing and hydraulic fracturing completions for mechanical fluid diversion and to reduce near wellbore damage. It is impossible to monitor the amount of ball sealers used in the oil and gas industry, although it is expected that all fields in the world have benefited economically in increasing production of oil and gas from ball sealers.

Reference:

1.Richard Nolen-Hoeksema (2013- ), Schlumberger Oilfield Glossary. Retrieved from http://www.glossary.oilfield.slb.com

2.Allison, Dave (2011), Restimulation of Wells using Biodegradable Particulates as Temporary Diverting Agents, Society of Petroleum Engineers, Paper 149221

3.Cockrell School. (2011, Jan 10) UT PGE Remembers Charles Simmons ’48. Retrieved from https://www.youtube.com

4.Kastrop, J. E., (1956), Newest Aid to Multi-Stage Fracturing, Society of Petroleum Engineers, Paper 553

5.Brow RW., Neill, G.H. and Loper, R.G. (1963), Factors Influencing Optimum Ball Sealer Performance, J. Pet. Tech. 450-454,Trans., AIME, 228.

6.Poyyara, Ragi, (2014), Optimization of Acid Treatments by Assessing Diversion Strategies in Carbonate and Sandstone Formations, World Academy of Science, Engineering and Technology International Journal of Chemical, Nuclear, Materials and Metallurgical Engineering Vol:8 No: Publication/9999335

7.Bern, P.A. and Lewis, R.C. 1992a. Ball Sealer Diversion in Deviated Wellbores. Interim Report, PEA/CEA Test Programme, Sunbury-on-Thames, UK

8.Biden, Dean, E (1998), New Water-Soluble Perforation Ball Sealers Provide Enhanced Diversion in Well Completions. Society of Petroleum Engineers, Paper 49099